|

DIMENSIONS (PN16) |

|||||||

|

Size |

L |

H |

ØD |

D1 |

n-Ød |

Plug |

W.T(kg ) |

|

DN15 |

130 |

65 |

95 |

65 |

4-Ø14 |

1/4" |

2 |

|

DN20 |

150 |

70 |

105 |

75 |

4-Ø14 |

1/4" |

2.3 |

|

DN25 |

160 |

80 |

115 |

85 |

4-Ø14 |

1/4" |

3.2 |

|

DN32 |

180 |

90 |

140 |

100 |

4-Ø19 |

1/4" |

5 |

|

DN40 |

200 |

135 |

150 |

110 |

4-Ø19 |

1/2" |

6.5 |

|

DN50 |

230 |

150 |

165 |

125 |

4-Ø19 |

1/2" |

8.7 |

|

DN65 |

290 |

160 |

185 |

145 |

4-Ø19 |

1/2" |

12 |

|

DN80 |

310 |

200 |

200 |

160 |

8-Ø19 |

1/2" |

19 |

|

DN100 |

350 |

240 |

220 |

180 |

8-Ø19 |

1/2" |

27 |

|

DN125 |

400 |

290 |

250 |

210 |

8-Ø19 |

3/4" |

40 |

|

DN150 |

480 |

330 |

285 |

240 |

8-Ø23 |

3/4" |

58 |

|

DN200 |

600 |

380 |

340 |

295 |

12-Ø23 |

3/4" |

86 |

|

DN250 |

730 |

480 |

405 |

355 |

12-Ø28 |

1" |

127 |

|

DN300 |

850 |

550 |

460 |

410 |

12-Ø28 |

1" |

200 |

|

DN350 |

980 |

661 |

520 |

470 |

16-Ø28 |

2" |

320 |

|

DN400 |

1100 |

739 |

580 |

525 |

16-Ø31 |

2" |

420 |

|

DN450 |

1200 |

830 |

640 |

585 |

20-Ø31 |

2" |

620 |

|

DN500 |

1250 |

910 |

715 |

650 |

20-Ø34 |

2" |

780 |

Materials

|

Body |

BS EN1563 EN-GJS-450-10 |

|

Cover |

BS EN1563 EN-GJS-450-10 |

|

Plug |

BSPT Zine Steel BSPT |

|

Gasket |

EPDM/NBR |

|

Bolt & Nut |

SS/Dacromet/ZY |

|

Screen |

SS Wire Screen/SS Perforated Mesh |

Specification

Design :DIN3352

Face To Face Length : DIN3202-F1

Elastomeric : EN681-2

Ductile Iron : BS EN1563

Coating :WIS4-52-01

Drilling Spec :EN1092-2

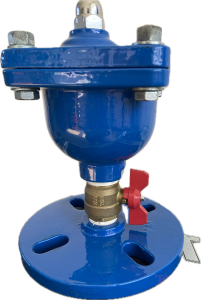

Product Description

The ductile iron Y-strainer is designed to withstand high pressure and temperature, making it suitable for use in a wide range of industrial applications. It is also easy to install and maintain, with a simple design that allows for easy cleaning and replacement of the strainer element.

A Y-strainer is a type of mechanical filter that is used to remove unwanted debris and particles from a fluid or gas stream. It is named after its shape, which resembles the letter "Y". The Y-strainer is typically installed in a pipeline or process system and is designed to capture and hold particles that are larger than the strainer's mesh or perforated screen.

The Y-strainer is made up of a body, cover, and screen or mesh. The body is typically made of cast iron, bronze, or stainless steel and is designed to withstand the pressure and temperature of the fluid or gas stream. The cover is usually bolted onto the body and can be removed for cleaning or maintenance. The screen or mesh is located inside the body and is designed to capture and hold particles.

Y-strainers are commonly used in a variety of industries, including chemical processing, oil and gas, water treatment, and HVAC systems. They are often installed upstream of pumps, valves, and other equipment to protect them from damage caused by debris and particles. Y-strainers are also used in steam systems to remove condensate and other contaminants.

Y-strainers come in a range of sizes and materials to suit different applications. They can be designed to handle high pressures and temperatures, corrosive fluids, and abrasive particles. Some Y-strainers are also equipped with a blowdown valve or drain plug to make cleaning and maintenance easier.

Ductile iron is a type of cast iron that is more flexible and durable than traditional cast iron. This makes it an ideal material for industrial applications where strength and durability are important.

The Y-strainer is typically installed in the pipeline before pumps, valves, and other equipment to protect them from damage caused by debris. It is commonly used in water treatment plants, chemical processing facilities, and oil and gas refineries.