Ductile iron loose flanged pipe fittings are a type of pipe fitting that is used to connect two or more pipes together. These fittings are made from ductile iron, which is a type of cast iron that is more flexible and durable than traditional cast iron. The loose flange design of these fittings allows for easy installation and removal, making them ideal for applications where frequent maintenance or repairs are required.

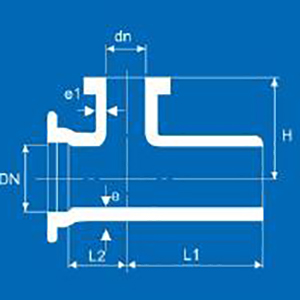

Ductile iron loose flanged pipe fittings come in a variety of shapes and sizes, including elbows, tees, reducers, and couplings. They are typically used in water and wastewater treatment plants, industrial applications, and municipal water systems. These fittings are designed to withstand high pressure and temperature, making them suitable for use in a wide range of applications.

One of the key benefits of ductile iron loose flanged pipe fittings is their durability. They are resistant to corrosion, abrasion, and impact, which makes them ideal for use in harsh environments. Additionally, these fittings are easy to install and require minimal maintenance, which helps to reduce downtime and increase productivity.

Overall, ductile iron loose flanged pipe fittings are a reliable and cost-effective solution for connecting pipes in a wide range of applications. Their durability, ease of installation, and low maintenance requirements make them an excellent choice for any piping system.

Internal Lining:

1. cement mortar,

2. Sulphuric Resistance Cement,

3. Sulphuric Resistance Cement and Epoxy,

4. H.A.cement;

External Coated:

1. zinc and bitumen,

2. zinc and 2 epoxy coatings,

3. Metallic Zinc and a coating of suitable etching prima and 2 Epoxy Coatings,

4. zinc and PU. Suitable medium: potable water, drainage, sewage, waste water. Suitable temperature: -40 centigrade degree - 125 centigrade degree.

Packing: plastic film plus pallet.

Origin: China.