Details

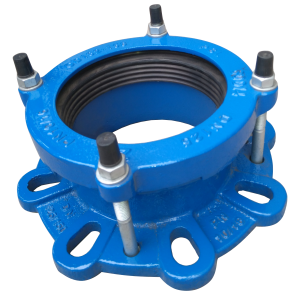

A ductile iron wide tolerance stepped coupling is a type of coupling used to connect two pipes or fittings of different sizes. It is made of ductile iron, which is a type of cast iron that is more flexible and durable than traditional cast iron.

The wide tolerance design of the coupling allows for a greater range of pipe sizes to be connected, reducing the need for multiple couplings and fittings. The stepped design of the coupling provides a secure and tight fit between the pipes, ensuring a leak-free connection.

Ductile iron wide tolerance stepped couplings are commonly used in water and wastewater treatment plants, as well as in industrial applications such as oil and gas pipelines. They are also used in plumbing and HVAC systems to connect pipes of different sizes.

Overall, ductile iron wide tolerance stepped couplings are a reliable and cost-effective solution for connecting pipes of different sizes, providing a secure and leak-free connection that can withstand the demands of various applications.

• Wide outside diameter range: an average of 21 mm by side.

• Small number of models for a Nominal Diameter.

• Reliability:

- Permanent leak tight joint when compressing the gasket

between the end-flange and the sleeve onto the pipe surface.

- Anticorrosion protection: epoxy powder coating (150 μm) and

Dacromet® 500 Gr.B for the bolts.

• Ease and speed of installation:

- Angular deflection ±6°.

- Absorbs expansion and contraction.

- Accommodates misalignment.

- Important setting gap.

• Conformity to standards:

- NF A 48-830: Foundry products - Spheroïdal graphite cast iron

fittings for PVC drinking water pipes under pressure.

- NF EN 545: Ductile iron pipes, fittings, accessories and their joints for

water pipelines - requirements and test methods.

- ISO 2531: Ductile iron pipes, fittings, accessories and their joints for

water applications.

• Approval:

- Drinking water approved.

• Nota:

This coupling does not resist to longitudinal forces and be sure

adequate restraint is provided to prevent pipes dislocation.

Technical data

• Range: DN 40/50 to 400.

• Maximal working pressure: PN 16.

• Temperatures: +0°C to +60°C.

• Torque: 60 to 70 Nm.

Applications

• Drinking water networks.

• Pumping, treatment, water storage.

• Fire protection networks.

• Irrigation networks.

• Sewage networks and rain waters drainage

(WC type - EN 681-1).

Tests

• Sealing test according to standard ISO 2531.

| Grooved Flange | |||||||

| Nominal Specification | Pressure | Dimension(mm) | |||||

| mm | inch | PN | H | D | F | d | B |

| 50 | 2 | 10 | 157 | 52 | 60.3 | 65 | 81 |

| 16 | 157 | 52 | 60.3 | 65 | 81 | ||

| 25 | 157 | 52 | 60.3 | 65 | 81 | ||

| 65 | 2.5 | 10 | 182 | 63 | 73 | 65 | 96.8 |

| 16 | 182 | 66 | 76.1 | 65 | 96.8 | ||

| 25 | 182 | 66 | 76.1 | 65 | 96.8 | ||

| 80 | 3 | 10 | 196 | 78.8 | 88.9 | 65 | 96.8 |

| 16 | 196 | 78.8 | 88.9 | 65 | 96.8 | ||

| 25 | 196 | 78.8 | 88.9 | 65 | 96.8 | ||

| 100 | 4 | 10 | 226 | 96.3 | 108 | 65 | 115.8 |

| 16 | 226 | 96.3 | 108 | 65 | 115.8 | ||

| 25 | 233 | 102.8 | 114.3 | 65 | 115.8 | ||

| 125 | 5 | 10 | 273 | 120.6 | 133 | 90 | 147.6 |

| 16 | 279 | 127.1 | 139.7 | 90 | 147.6 | ||

| 25 | 279 | 127.1 | 141.3 | 90 | 147.6 | ||

| 150 | 6 | 10 | 298 | 145.1 | 159 | 90 | 147.6 |

| 16 | 303 | 151.6 | 165.1 | 90 | 147.6 | ||

| 25 | 303 | 151.6 | 168.3 | 90 | 147.6 | ||

| 200 | 8 | 10 | 369 | 230.4 | 219.1 | 90 | 133.4 |

| 16 | 369 | 230.4 | 219.1 | 90 | 133.4 | ||

| 25 | 369 | 230.4 | 219.1 | 90 | 133.4 | ||