Product Description

About Double Orifice Air Release Valve:

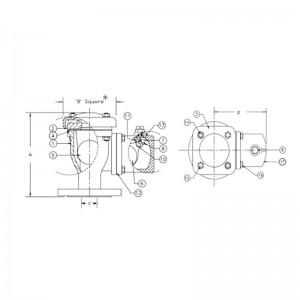

A double orifice air release valve is a type of valve used in pipelines to release air and other gases that may accumulate in the system. It has two orifices, one for air release and the other for vacuum relief. The air release orifice is used to release air from the pipeline when it is filled with water, while the vacuum relief orifice is used to allow air to enter the pipeline when there is a vacuum created due to water flow or other factors. This valve helps to prevent damage to the pipeline by maintaining the proper pressure and preventing air pockets from forming.

Double orifice air valve that combines both large orifice & small orifice functions within one unit.The large orifice allows air to be expelled from the system during filling of a pipeline and admit air back into the system whenever sub-atmospheric pressure occurs.Air is vented from the system until water enters the valve and lifts the float against its seat,ensuring a tight seal.In the event of sub-atmospheric pressure in the system,the water level drops causing the float to fall from its seat and allow the admission of air.

During normal working of the main the small orifice releases the air which accumulates under pressure.With the main in operation,the float is normally against its seat.As air enters the chamber body the water level is depressed until a level is reached when the float drops form its seat,whcih allows air to escape.The consequent rise in water level returns the float to its seat.

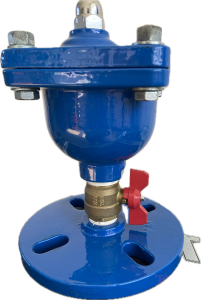

A ductile iron double orifice air release valve is a type of valve used in water distribution systems to release air from the pipeline. It is designed to prevent air pockets from forming in the pipeline, which can cause problems such as reduced flow, increased pressure, and damage to the pipeline.

The valve is made of ductile iron, which is a type of cast iron that is more flexible and durable than traditional cast iron. This makes it more resistant to cracking and breaking under pressure, which is important in water distribution systems.

The double orifice design of the valve allows for air to be released from both the top and bottom of the valve, which helps to ensure that all air pockets are removed from the pipeline. This helps to maintain a consistent flow of water and prevent damage to the pipeline.

Overall, the ductile iron double orifice air release valve is an important component of water distribution systems, helping to ensure that water is delivered efficiently and reliably to consumers.

DESIGN

- The cross-sectional area of the valve body channel at each part of the valve is equal to or greater than the area corresponding to the nominal pipe diameter. The funnel valve body channel design conforms to the aerodynamic principle to ensure that the exhaust under large pressure difference will not be blocked. Large diameter circular floats to increase buoyancy seal more reliably. A threaded port is required on the side of the valve to flush the valve in line without removing the valve from the line.

- The secondary micro-exhaust function and the main valve are integrated to avoid redundant leakage points. The micro-exhaust float adopts the lever sealing principle, the float is sensitive and the sealing is reliable.

- The sealing ring is a whole vulcanized structure, and is reinforced with steel lining. It is designed by self-sealing principle and has a 10-year shelf life. It can meet the sealing under no pressure and no damage under high pressure conditions.

- The characteristics of the waterproof hammer are realized by the current-limiting check valve, which can be designed and manufactured according to different working conditions. The valve plate has adjustment holes, and the factory current-limiting area is 90% of the channel. The anti-backflow characteristic is realized by the exhaust valve backflow preventer. Even if the exhaust valve is immersed in polluted water, it can exhaust normally without water.

The floating body shall be subjected to 2x pressure test in accordance with the requirements of CJ/T216-2013, and the test results shall show no water intake, cracking or deformation, and no change in weight.

Material

- The structure of the valve body and cover shall be of QT500-7 ductile iron, and the body material of choice shall include corrosion-resistant austenitic ductile iron.

- The sealing ring should be made of nitrile butadiene rubber (NBR) or EPDM, and the materials available also include fluorine rubber.

- The material of the floating body is 316 stainless steel.

Cases where additional products are available:

- Install a water hammer preventer where water hammer occurs. If the fluctuation of the pipeline is large, the water hammer will be closed. A water hammer preventer should also be installed.

- Pipe exhaust valves in low-lying areas may be soaked by sewage. Install an exhaust valve backflow preventer to prevent drinking water pollution.

- Corrosion-resistant austenitic ductile iron is used when there is a corrosive medium such as seawater.