Materials

|

Body |

Ducitle Iron |

Specification

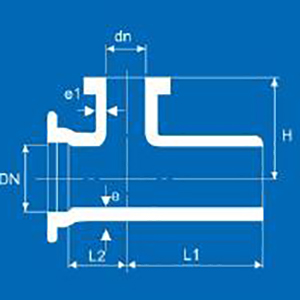

An All-Flanged Tee with 45° Angle Branch, also known as an All-Flanged "Y" Tee, is a type of pipe fitting that is designed to connect three pipes at a 45° angle. It is commonly used in piping systems where a branch line needs to be connected to a main line at an angle. The All-Flanged Tee with 45° Angle Branch is made up of three flanged ends, with one end being larger than the other two. The larger end is the main line, while the smaller ends are the branch lines.

The All-Flanged Tee with 45° Angle Branch is made from high-quality materials such as carbon steel, stainless steel, and alloy steel. These materials are chosen for their strength, durability, and resistance to corrosion. The flanged ends of the tee are designed to be bolted together, creating a tight and secure seal that prevents leaks and ensures the smooth flow of fluids through the piping system.

One of the key advantages of the All-Flanged Tee with 45° Angle Branch is its versatility. It can be used in a wide range of applications, including oil and gas, chemical processing, and water treatment. It is also suitable for use in high-pressure and high-temperature environments, making it a popular choice for demanding industrial applications.

In conclusion, the All-Flanged Tee with 45° Angle Branch is a highly versatile and reliable pipe fitting that is widely used in a variety of industries. Its robust construction, high-quality materials, and secure flanged connections make it an ideal choice for connecting three pipes at a 45° angle.

The All-Flanged Tee with 45° Angle Branch is a type of pipe fitting that is used to connect three pipes at a 45-degree angle. It is commonly used in piping systems where there is a need to change the direction of flow or to branch off a pipe at a specific angle.

The application of All-Flanged Tee with 45° Angle Branch is mainly in the oil and gas industry, chemical plants, and other industrial applications. It is used in pipelines that transport fluids such as oil, gas, water, and chemicals. The fitting is designed to withstand high pressure and temperature, making it suitable for use in harsh environments.