Materials

|

Body |

Ducitle Iron |

|

Seals |

EPDM/NBR |

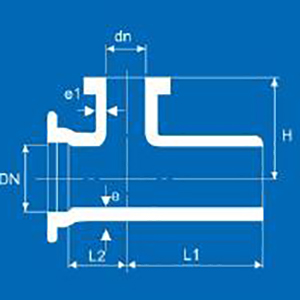

Specification

A 90° double-flanged long radius bend is a type of pipe fitting that is used to change the direction of a pipeline by 90 degrees. It is designed with two flanges on each end, which allows for easy installation and connection to other pipes or fittings. The long radius bend has a larger radius than a short radius bend, which helps to reduce the amount of friction and pressure drop in the pipeline.

The double-flanged design of the long radius bend provides a secure and leak-proof connection between pipes. The flanges are bolted together, creating a tight seal that prevents any fluid from leaking out of the pipeline. This makes the long radius bend ideal for use in applications where a high level of reliability and safety is required.

The 90° double-flanged long radius bend is commonly used in industries such as oil and gas, chemical processing, and water treatment. It is often used to connect pipes that are located at different angles or to change the direction of a pipeline to avoid obstacles or other obstructions.

One of the key benefits of using a long radius bend is that it helps to reduce the amount of stress and strain on the pipeline. The larger radius of the bend allows for a smoother transition between pipes, which helps to minimize the risk of damage or failure due to excessive pressure or vibration.

In addition to its functional benefits, the 90° double-flanged long radius bend is also easy to install and maintain. The flanged design allows for quick and easy connection to other pipes or fittings, and the bend itself can be easily removed or replaced if necessary.

Overall, the 90° double-flanged long radius bend is a versatile and reliable pipe fitting that is widely used in a variety of industries. Its unique design and construction make it an ideal choice for applications where a high level of performance and safety is required.